Why Granite needs more attention?

Granite is comparatively harder in nature and in the same way it requires good preservation. These are stones which are highly durable in nature yet prone to scratches, dust and attract deposits that fall on the surface like rust stains, oil stains, etc. Cleaning the surface is mandatory if the quality of the stone has to be maintained.

Classification of Maintenance Tips

Granite floors need routine and regular maintenance to sustain in their appearance and texture. It can be classified into initial and periodic maintenance

Initial Preservation

Initial aspects of cleaning and preservation includes dust mopping and wet mopping by using floor cleaning liquids which do not cause any damage or reaction on the stone surface.

Scrubbing the floor on periodic basis can help to maintain the polished surface. Machine scrubbing is most suitable after which cleaning or rinsing with fresh water may help to preserve floors in good condition for long term.

Curative Maintenance

This type of cleaning is required for those who wish to see the floor fresh and new. It involved specialized form of cleaning like grinding, polishing and honing which can be done with professional assistance only. This method is comparatively expensive however, helps to obtain fresh look to the stones.

Polishing Tips

Manual polishing may help to get rid of dust or stains to some extent. It will work only if stains are not allowed to rest for long time. However, application of polishing tools which are exclusively meant for granite stone have to be used to reach perfection.

Selecting a Suitable Polishing Equipment

It is not that granite stone absorbs less water it has various interlace minerals which can be found when you magnify and see the stone pattern. There will be slight pores and voids which attract water and if water gets into it will cause unfavorable effects on the stone quality resulting in cracks. Selection of suitable polishing tool plays an important role in this regard.

Granite Polishing Machine Head

When it comes to selection of tool for maintenance, polishing head has to be checked for compatibility with the stone. Granite polishing machine head is exclusively designed for this purpose. This can be added along with the existing buffing equipment. It stays compatible for both marble and granite and never leaves scratches. Above all, it is energy efficient, resistance to corrosion when compared to traditional polishing heads.

Professional Support

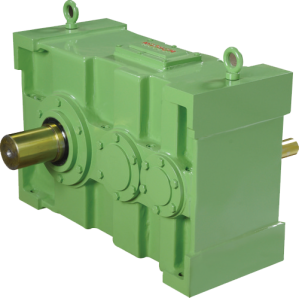

Professional support remains mandatory for extreme maintenance and they can work only with the help of machines that are exclusively designed for this purpose. Yogesh Engineering Works offers granite polishing machine head made of superior quality of raw material. Our gadget is compatible for both marble and granite stones. It will remain a durable option for long term maintenance requirement. We also provide industry supportive helical gearbox, extruder helical gearbox, reduction gearbox and timely belt pulley in tune with various industrial requirements. For more information about helical gearbox, visit – http://www.yogeshengg.com/products/helical-gearbox/

Conclusion

Granite is comparatively harder stone yet it attracts scratches it is not applied with the right kind of polishing technique. If we go for professional maintenance support selection of equipment with suitable cleaning gadgets can help to reach perfect shining.